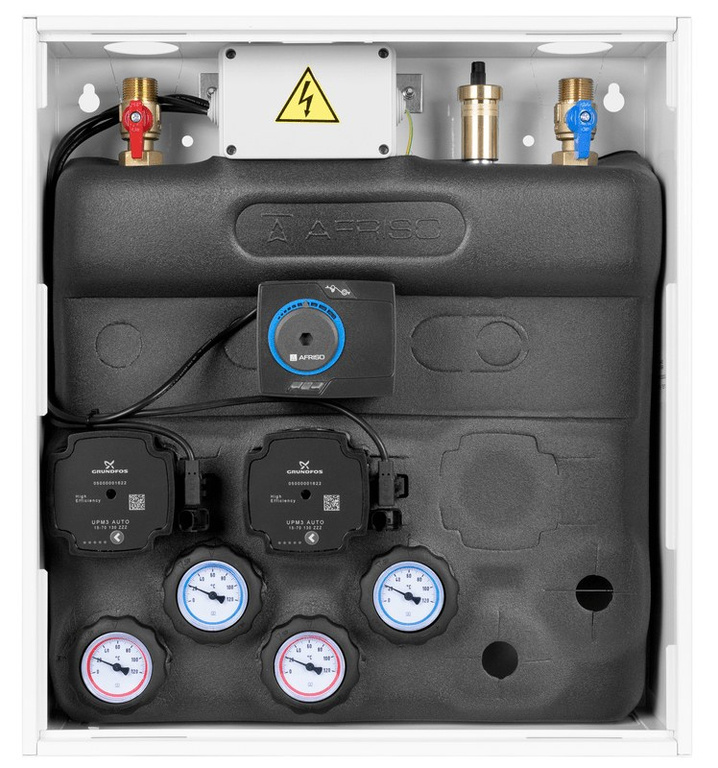

PrimoBox AZB 205 mixing set in cabinet, without mixing, rotary valve with ARM 141 actuator

- The PrimoBox AZB 205 mixing set in a cabinet, with a rotary valve and ARM 141 actuator, is used to separate a heat source from 2-3 heating zones. It allows temperature management by mixing or direct supply.

Subscription products in your shopping cart

Set one delivery frequency for all subscription products in your cart every:

Subscription products in your shopping cart

Brand

Symbol

76 205 00

Producer code

5902510003814

Series

Warranty

Manufacturer's Index

7620500

PrimoBox AZB 205 mixing set with hydraulic coupling

PrimoBox AZB 205 is a compact hydraulic kit that integrates two circuits in one cabinet: - circuit without mixing (direct) - circuit with ARV mixing valve and ARM ProClick actuator The kit also comes with a hydraulic coupling, which ensures pressure stability between circuits The maximum power of the kit is **35 kW**

Application

- Heating systems with the need to separate circuits

- Systems requiring temperature control in one of the circuits

- Upgrades or new boiler plants where a quick and clean hydraulic solution is required

- Use in systems with pumps, where hydraulic separation increases the stability of operation

Technical data

| Circuit 1 | Direct (without mixing) |

| Circuit 2 | Mixing - ARV valve with actuator |

| Kvs range of the valve | 3.6 m³/h |

| Hydraulic coupling | Yes (included) |

| Maximum power | 35 kW |

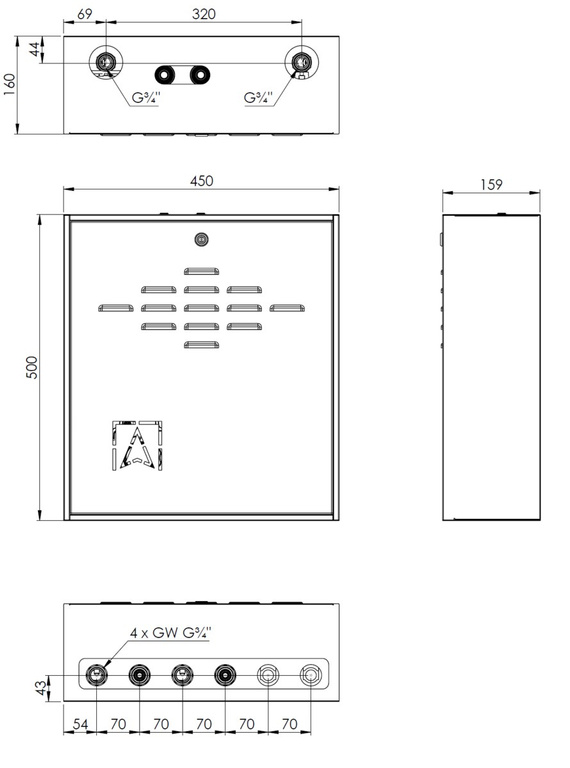

| Connections from the source side | G¾" threads |

| Pressure of medium | max 4,5 bar |

| Temperature of medium | max 95 °C |

Advantages and distinctive features

- Complete prefabricated kit in a cabinet - saves assembly time

- Hydraulic coupling for stability between circuits

- Mixing circuit with ARV valve and ARM ProClick actuator - ease of control

- Aesthetics and orderliness of the installation thanks to integrated design

- High usability in retrofits and new installations

Installation and operation tips

- Mount the kit in a position that allows access to the valve, pumps and coupling

- Before commissioning, bleed the installation and check for leaks

- Set the mixing valve actuator correctly - movement limiters 0-10 or 10-0

- Avoid exceeding the permissible parameters (pressure, temperature)

- Regularly check the condition of valves, pumps and tightness of connections

Ask a question

Write your opinion